| Factory Audit | Random Check | Full Check | |

| Visit factory | Y | Y | Y |

| Factory background | Y | ||

| Random Check | Y | ||

| 100% check | Y | ||

| Packing list | Y | Y | |

| Inspection report | Y | Y | Y |

| Delivery time | 1 day | 1 day | 1-3 days |

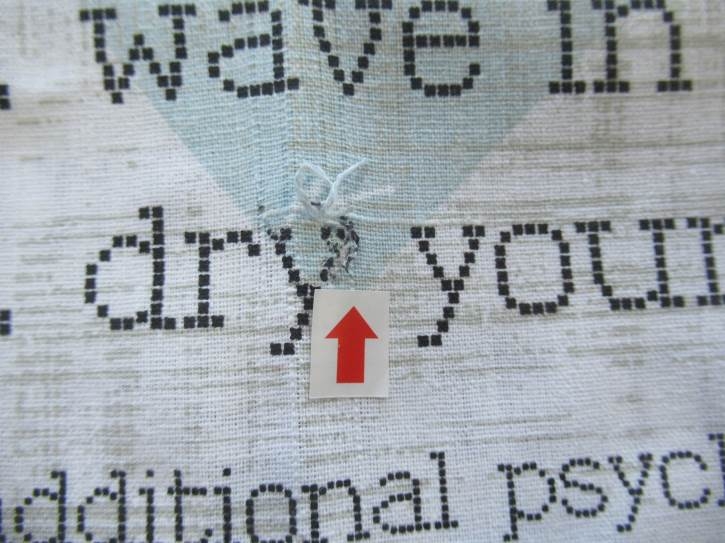

Textile inspection

Grocery toy product inspection

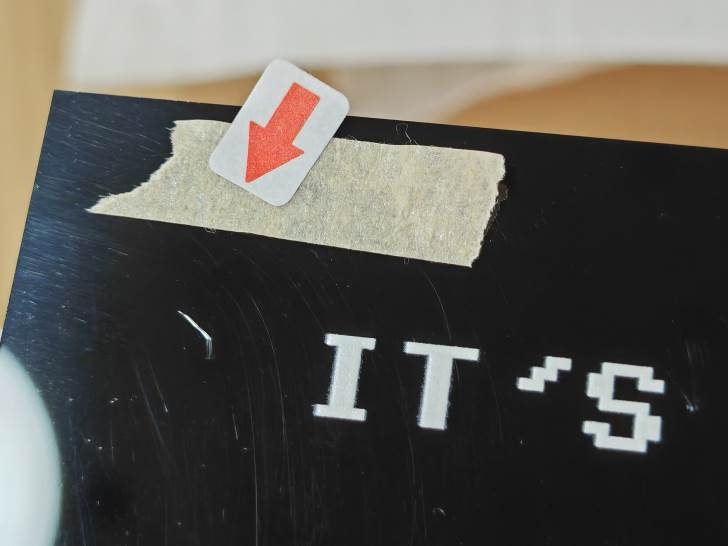

Electronic and electrical products inspection

Industrial product inspection

A comprehensive third-party authoritative assessment and review of the supplier‘s including: business qualification and environment, production capacity and equipment, quality management and warehousing and other key information directly in contact with the production source, and issue a supplier audit report with authority and credibility that has been certified by the blockchain certificate and notary office

| MIL-STD-105E | |||||||||||||||||||||||||

| Quantity | Level | Mark | Sample Quantity | Acceptable Quality Levels | |||||||||||||||||||||

| I. | II. | III. | 0.01 | 0.015 | 0.025 | 0.04 | 0.065 | 0.1 | 0.15 | 0.25 | 0.4 | 0.65 | 1 | 1.5 | 2.5 | 4 | 6.5 | 10 | 15 | 25 | |||||

| AcRe | AcRe | AcRe | AcRe | AcRe | AcRe | AcRe | AcRe | AcRe | AcRe | AcRe | AcRe | AcRe | AcRe | AcRe | AcRe | AcRe | AcRe | ||||||||

| 2 | – | 8 | A | A | B | A | 2 | 0 1 | 1 2 | ||||||||||||||||

| 9 | – | 15 | A | B | C | B | 3 | 0 1 | 1 2 | 2 3 | |||||||||||||||

| 16 | – | 25 | B | C | D | C | 5 | 0 1 | 1 2 | 2 3 | 3 4 | ||||||||||||||

| 26 | – | 50 | C | D | E | D | 8 | 0 1 | 1 2 | 2 3 | 3 4 | 5 6 | |||||||||||||

| 51 | – | 90 | C | E | F | E | 13 | 0 1 | 1 2 | 2 3 | 3 4 | 5 6 | 7 8 | ||||||||||||

| 91 | – | 150 | D | F | G | F | 20 | 0 1 | 1 2 | 2 3 | 3 4 | 5 6 | 7 8 | 10 11 | |||||||||||

| 151 | – | 280 | E | G | H | G | 32 | 0 1 | 1 2 | 2 3 | 3 4 | 5 6 | 7 8 | 10 11 | 14 15 | ||||||||||

| 281 | – | 500 | F | H | J | H | 50 | 0 1 | 1 2 | 2 3 | 3 4 | 5 6 | 7 8 | 10 11 | 14 15 | 21 22 | |||||||||

| 501 | – | 1200 | G | J | K | J | 80 | 0 1 | 1 2 | 2 3 | 3 4 | 5 6 | 7 8 | 10 11 | 14 15 | 21 22 | |||||||||

| 1201 | – | 3200 | H | K | L | K | 125 | 0 1 | 1 2 | 2 3 | 3 4 | 5 6 | 7 8 | 10 11 | 14 15 | 21 22 | |||||||||

| 3201 | – | 10000 | J | L | M | L | 200 | 0 1 | 1 2 | 2 3 | 3 4 | 5 6 | 7 8 | 10 11 | 14 15 | 21 22 | |||||||||

| 10001 | – | 35000 | K | M | N | M | 315 | 0 1 | 1 2 | 2 3 | 3 4 | 5 6 | 7 8 | 10 11 | 14 15 | 21 22 | |||||||||

| 35001 | – | 2E+05 | L | N | P | N | 500 | 0 1 | 1 2 | 2 3 | 3 4 | 5 6 | 7 8 | 10 11 | 14 15 | 21 22 | |||||||||

| 2E+05 | – | 5E+05 | M | P | Q | P | 800 | 0 1 | 1 2 | 2 3 | 3 4 | 5 6 | 7 8 | 10 11 | 14 15 | 21 22 | |||||||||

| 5E+05 | – | over | N | Q | R | Q | 1250 | 0 1 | 1 2 | 2 3 | 3 4 | 5 6 | 7 8 | 10 11 | 14 15 | 21 22 | |||||||||

| R | 2000 | 1 2 | 2 3 | 3 4 | 5 6 | 7 8 | 10 11 | 14 15 | 21 22 | ||||||||||||||||

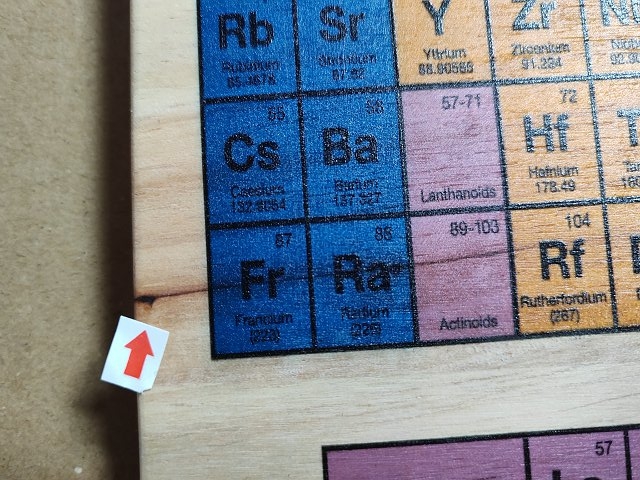

(Ply wood)

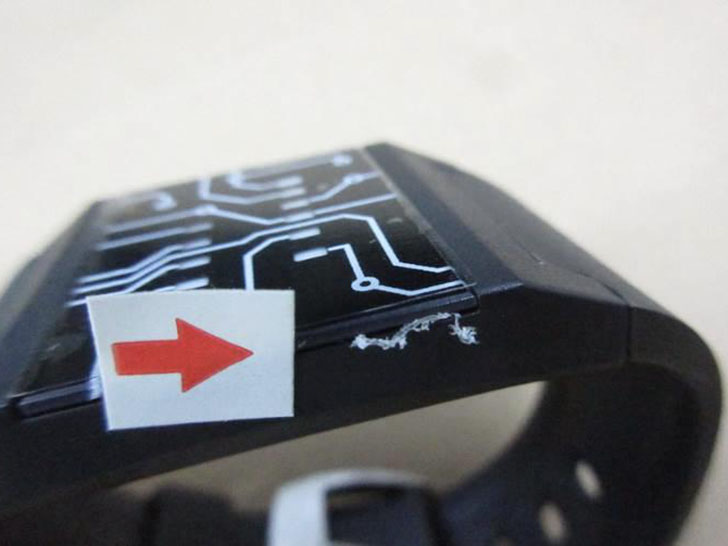

(Household appliances)

(Solid wood)

(Electronics)

(Metal)

(Textile)

Mid-production inspection (DUPRO) means that Sworld can be commissioned to conduct sample inspection of products when the batch product is 30%-50% complete. Mid-production inspection can reconfirm whether the factory is in accordance with the original production quality requirements and processes. If there are new raw materials, parts, new operators, new production lines, or changes in product specifications during the production process, mid-production inspection can confirm whether the quality of the adjusted products meets the requirements of customers.

A comprehensive third-party authoritative assessment and review of the supplier‘s including: business qualification and environment, production capacity and equipment, quality management and warehousing and other key information directly in contact with the production source, and issue a supplier audit report with authority and credibility that has been certified by the blockchain certificate and notary office

Loading Supervision refers to the loading of goods into containers safely, accurately and properly under the on-site supervision of the loading personnel, usually the inspectors, so as to ensure that your goods are safely loaded and ready for shipment under good conditions. After the completion of supervision, a detailed supervision report will be issued to the customer within 24 hours.